Odes s.r.o. se v posledních letech intenzivně zabývá výrobou třídících linek pro komunální odpad, kde na výstupu najdeme suroviny k dalšímu prodeji, spolu s alternativním palivem a dalšími komoditami. S výsledkem naší práce se můžete setkat nejen v ČR.

Tyres shredding for incineration

Used tyres can be shredded to the output size which allows the use of brash as an alternative fuel, mainly in the cement plants. For obtaining the clinker in cement technology production the metallic cord in tyre is an additional raw material. Due to high heating value of shredded tyres they might be burnt in incinerators.

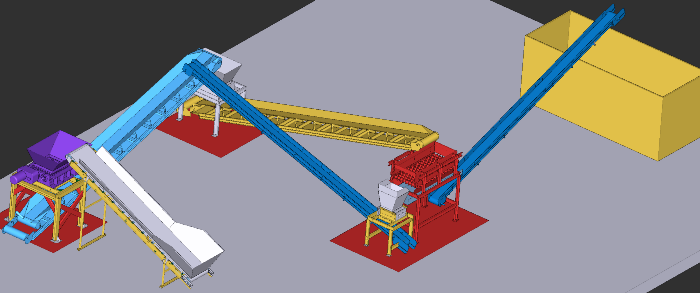

The tyres are shredded in double-shaft shredders in two or three degrees. The resulting brash on the sorting sieve is divided to the under-sieve output fraction and the above-sieve output fraction which returns again back to the technology line for shredding to required size. The size of the output fraction is adjustable by the technical specification of the sorter. The most common used size of the output fraction is 50x50mm or 100x100mm. The capacity of the line may be about 1000-2500kg/h. Line with this purpose may be used as a first part of the preparation of tyres before entering to the line for getting the clean rubber granulate.

Due to higher amount of the initial investment, the hourly capacity of the line and value added obtained from the raw material is the most effective way of processing waste tyres.

Production line for tyres processing (Illustration picture)

Technology

Maecenas fermentum

Nullam viverra purus

Maecenas nec pulvinar leo

© 2014, Odes s.r.o.

Webové stránky vytvořilo eStudio.cz | Webdesign & SEO | Postaveno na ReflexCMS